3D Manufacturing

3D Manufacturing

Written By:

Guest post - Date published:

9:32 am, April 13th, 2013 - 125 comments

Categories: Economy -

Tags: 3D printer peril, hi-tech, manufacturing, technology

Heard of this one a few weeks ago:

Heard of this one a few weeks ago:

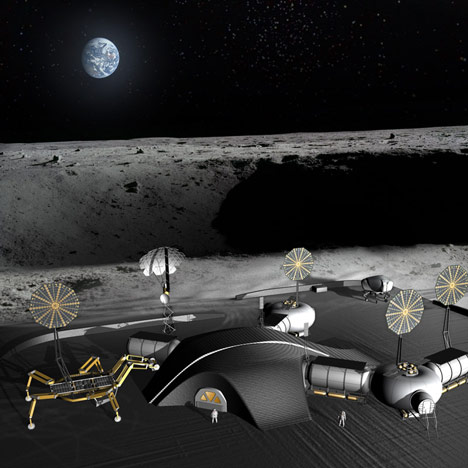

Tomas Rousek, Katarina Eriksson and Dr. Ondrej Doule are collaborating with NASA’s Jet Propulsion Laboratory on plans for a modular architectural structure at the lunar south pole. Each module would be printed using a NASA robotic system, which would produce a ceramic-like material by microwave-sintering lunar soil, also known as regolith. There would be no need for glue, as the particles would naturally bond themselves together when heated to the right temperature by the robots.

And this one came across the Twitter feed:

A three-dimensional (3D) printer powered by sunlight has been developed with the aim of turning desert sand into glass. Now, experts are recognising the device as a promising first step towards a future large-scale industry.

It seems that 3D Printing is really starting to mature. Such printers are becoming smaller, cheaper and more capable. The first article I linked to shows that it’s only a matter of time before builders become obsolete. Both articles show that a lot can be done with the diffuse energy of the sun.

Although it has a ways to go 3D printing is, IMO, the next level in manufacturing. It produces less waste than traditional forms and is far more flexible. Parts could be made on site from local raw resources rather than being mass produced in a dedicated factory based on the old manufacturing model and then being shipped around the world. There is some doubt that 3D printing capability of reaching the same speed that traditional manufacturing can but I believe that will be addressed in time.

The first major effect of 3D printing though will be the fact that even small communities will be able to afford 3D manufacturing facilities. As I said, they’re small and cheap compared to traditional factories which means that trade will become less and less of an option – especially international trade. No more exporting ourselves to wealth (not that that was ever going to work).

The neo-liberals will get the perfect competition that they’ve dreamed of and it will be their nightmare. When everyone can manufacture whatever they need and designs can easily be shared across the internet then the artificial restrictions (Think patents and copyright) that the capitalists have been building up for the last few centuries will break. Profits will crash, jobs will disappear and poverty will be rampant. At that point we will have to make a choice – to work together or to try to keep capitalism going and the latter isn’t an option.

Draco T Bastard

Related Posts

125 comments on “3D Manufacturing ”

- Comments are now closed

- Comments are now closed

Recent Comments

- Ad to Res Publica on

- Bearded Git to arkie on

- Kay on

- Ad to Bearded Git on

- aj on

- arkie to Res Publica on

- Res Publica to Ad on

- Res Publica on

- Bearded Git to Ad on

- SPC on

- Res Publica to arkie on

- Res Publica to Ad on

- arkie to Res Publica on

- Res Publica to Ad on

- Ad to Bearded Git on

- Tiger Mountain to Ad on

- Ad on

- Tiger Mountain to Bearded Git on

- weka to Bearded Git on

- Bearded Git on

- Bearded Git to Ad on

- Res Publica to Ad on

- Psycho Milt on

- joe90 on

- Ad to Bearded Git on

- joe90 to Bearded Git on

- Bearded Git on

- Bearded Git on

- Ad to Res Publica on

- Res Publica to Ad on

- SPC on

- Ad on

- SPC on

- SPC to Drowsy M. Kram on

- SPC to Res Publica on

- SPC on

- Drowsy M. Kram to Res Publica on

- Cricklewood to dv on

- Res Publica to Belladonna on

- Belladonna to Res Publica on

- dv on

- Darien Fenton to lprent on

Recent Posts

-

by advantage

-

by weka

-

by Mike Smith

-

by mickysavage

-

by KJT

-

by Mike Smith

-

by eugenedoyle

-

by advantage

-

by mickysavage

-

by weka

-

by mickysavage

-

by mickysavage

-

by mickysavage

-

by Incognito

-

by lprent

-

by Mountain Tui

-

by mickysavage

-

by Incognito

-

by Mountain Tui

-

by advantage

-

by Guest post

-

by mickysavage

-

by lprent

-

by weka

-

by advantage

-

by Guest post

- Chris Penk’s Leaky Homes 2.0

The Coalition of Chaos is at it again with another half-baked underwhelming scheme that smells suspiciously like a rerun of New Zealand’s infamous leaky homes disaster. Their latest brainwave? Letting tradies self-certify their own work on so-called low-risk residential builds. Sounds like a great way to cut red tape to ...28 minutes ago

The Coalition of Chaos is at it again with another half-baked underwhelming scheme that smells suspiciously like a rerun of New Zealand’s infamous leaky homes disaster. Their latest brainwave? Letting tradies self-certify their own work on so-called low-risk residential builds. Sounds like a great way to cut red tape to ...28 minutes ago - Assumed Competence

Perfect by natureIcons of self indulgenceJust what we all needMore lies about a world thatNever was and never will beHave you no shame don't you see meYou know you've got everybody fooledSongwriters: Amy Lee / Ben Moody / David Hodges.“Vote National”, they said. The economic managers par excellence who will ...Nick’s KōreroBy Nick Rockel2 hours ago

Perfect by natureIcons of self indulgenceJust what we all needMore lies about a world thatNever was and never will beHave you no shame don't you see meYou know you've got everybody fooledSongwriters: Amy Lee / Ben Moody / David Hodges.“Vote National”, they said. The economic managers par excellence who will ...Nick’s KōreroBy Nick Rockel2 hours ago - The ADF isn’t nearly fast enough. It must rush into the cheap-drone revolution

The Australian Defence Force isn’t doing enough to adopt cheap drones. It needs to be training with these tools today, at every echelon, which it cannot do if it continues to drag its feet. Cheap drones ...The StrategistBy Erik Davis2 hours ago

The Australian Defence Force isn’t doing enough to adopt cheap drones. It needs to be training with these tools today, at every echelon, which it cannot do if it continues to drag its feet. Cheap drones ...The StrategistBy Erik Davis2 hours ago - “You and me need to hang out. As in, just us 2!”

Hi,Just over a year ago — in March of 2024 — I got an email from Jake. He had a story he wanted to tell, and he wanted to find a way to tell it that could help others. A warning, of sorts. And so over the last year, as ...David FarrierBy David Farrier3 hours ago

Hi,Just over a year ago — in March of 2024 — I got an email from Jake. He had a story he wanted to tell, and he wanted to find a way to tell it that could help others. A warning, of sorts. And so over the last year, as ...David FarrierBy David Farrier3 hours ago - National Has Mismanaged The Economy

Back in the dark days of the pandemic, when the world was locked down and businesses were gasping for air, Labour’s quick thinking and economic management kept New Zealand afloat. Under Jacinda Ardern and Grant Robertson, the Wage Subsidy Scheme saved 1.7 million jobs, pumping billions into businesses to stop ...4 hours ago

Back in the dark days of the pandemic, when the world was locked down and businesses were gasping for air, Labour’s quick thinking and economic management kept New Zealand afloat. Under Jacinda Ardern and Grant Robertson, the Wage Subsidy Scheme saved 1.7 million jobs, pumping billions into businesses to stop ...4 hours ago - Bernard’s Picks ‘n’ Mixes at 6am on Tuesday, April 29

The Big Six at 6am on Tuesday, April 29Politics news by NZ Herald: Tory Whanau exits Wellington mayoral race, reveals why she's not running again & RNZ: Tory Whanau quits Wellington mayoral raceHealth news scoop by Marc Daalder for Newsroom Pro-$: Weekly data reveals scale of Govt’s waiting list crisis.’ ...The KakaBy Bernard Hickey4 hours ago

The Big Six at 6am on Tuesday, April 29Politics news by NZ Herald: Tory Whanau exits Wellington mayoral race, reveals why she's not running again & RNZ: Tory Whanau quits Wellington mayoral raceHealth news scoop by Marc Daalder for Newsroom Pro-$: Weekly data reveals scale of Govt’s waiting list crisis.’ ...The KakaBy Bernard Hickey4 hours ago - No going back

When I was fifteen I discovered the joy of a free bar. All you had to do was say Bacardi and Coke, thanks to the guy in the white shirt and bow tie. I watched my cousin, all private school confidence, get the drinks in, and followed his lead. Another, ...More Than A FeildingBy David Slack4 hours ago

When I was fifteen I discovered the joy of a free bar. All you had to do was say Bacardi and Coke, thanks to the guy in the white shirt and bow tie. I watched my cousin, all private school confidence, get the drinks in, and followed his lead. Another, ...More Than A FeildingBy David Slack4 hours ago - Beijing finally slices off Sandy Cay

The Financial Times reported last week that China’s coast guard has declared China’s sovereignty over Sandy Cay, posting pictures of personnel holding a Chinese flag on a strip of sand. The landing apparently took place ...The StrategistBy Euan Graham17 hours ago

The Financial Times reported last week that China’s coast guard has declared China’s sovereignty over Sandy Cay, posting pictures of personnel holding a Chinese flag on a strip of sand. The landing apparently took place ...The StrategistBy Euan Graham17 hours ago - National’s Stalling New Zealand’s Electric Future

You might not know this, but New Zealand’s at the bottom of the global league table for electric vehicle (EV) chargers, and the National government’s policies are ensuring we stay there, choking the life out of our clean energy transition.According to the International Energy Agency’s 2024 Global EV Outlook, we’ve ...17 hours ago

You might not know this, but New Zealand’s at the bottom of the global league table for electric vehicle (EV) chargers, and the National government’s policies are ensuring we stay there, choking the life out of our clean energy transition.According to the International Energy Agency’s 2024 Global EV Outlook, we’ve ...17 hours ago - EGU2025 – Presentation about our collaborations

As mentioned in the recently published prolog to EGU2025 article, I submitted an abstract to talk about some of the collaborations we've had with other groups and websites over the years. This blog post is a "companion article" to that presentation in session EOS1.1 Science and Society: Science Communication Practice, Research, and ...18 hours ago

As mentioned in the recently published prolog to EGU2025 article, I submitted an abstract to talk about some of the collaborations we've had with other groups and websites over the years. This blog post is a "companion article" to that presentation in session EOS1.1 Science and Society: Science Communication Practice, Research, and ...18 hours ago - Rudd and Shearer aren’t enough. Washington needs to see more Australian heavy hitters

We need more than two Australians who are well-known in Washington. We do have two who are remarkably well-known, but they alone aren’t enough in a political scene that’s increasingly influenced by personal connections and ...The StrategistBy Justin Bassi18 hours ago

We need more than two Australians who are well-known in Washington. We do have two who are remarkably well-known, but they alone aren’t enough in a political scene that’s increasingly influenced by personal connections and ...The StrategistBy Justin Bassi18 hours ago - “Protecting frontline services”

When National embarked on slash and burn cuts to the public service, Prime Minister Chris Luxon was clear that he expected frontline services to be protected. He lied: The government has scrapped part of a work programme designed to prevent people ending up in emergency housing because the social ...No Right TurnBy Idiot/Savant19 hours ago

When National embarked on slash and burn cuts to the public service, Prime Minister Chris Luxon was clear that he expected frontline services to be protected. He lied: The government has scrapped part of a work programme designed to prevent people ending up in emergency housing because the social ...No Right TurnBy Idiot/Savant19 hours ago - Climate Change: National supports pollution subsidies

When the Emissions Trading Scheme was originally introduced, way back in 2008, it included a generous transitional subsidy scheme, which saw "trade exposed" polluters given free carbon credits while they supposedly stopped polluting. That scheme was made more generous and effectively permanent under the Key National government, and while Labour ...No Right TurnBy Idiot/Savant20 hours ago

When the Emissions Trading Scheme was originally introduced, way back in 2008, it included a generous transitional subsidy scheme, which saw "trade exposed" polluters given free carbon credits while they supposedly stopped polluting. That scheme was made more generous and effectively permanent under the Key National government, and while Labour ...No Right TurnBy Idiot/Savant20 hours ago - Atlas Network Makes Australian Mainstream

Australia Shows The WayAustralian media and their investigative journalists have published two articles on the Atlas Network’s modus operandi in recent weeks:‘Copied the MAGA model’: The ‘grassroots’ lobby group funded by some of Australia’s richestHow Atlas Network amassed a global network of free market think tanks and reached into Australia ...Mountain TuiBy Mountain Tūī23 hours ago

Australia Shows The WayAustralian media and their investigative journalists have published two articles on the Atlas Network’s modus operandi in recent weeks:‘Copied the MAGA model’: The ‘grassroots’ lobby group funded by some of Australia’s richestHow Atlas Network amassed a global network of free market think tanks and reached into Australia ...Mountain TuiBy Mountain Tūī23 hours ago - Australia’s defence readiness—a critical assessment

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Malcolm Davis23 hours ago

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Malcolm Davis23 hours ago - The Suspicious Death of Virginia Giuffre

The news of Virginia Giuffre’s untimely death has been a shock, especially for those still seeking justice for Jeffrey Epstein’s victims. Giuffre, a key figure in exposing Epstein’s depraved network and its ties to powerful figures like Prince Andrew, was reportedly struck by a bus in Australia. She then apparently ...1 day ago

The news of Virginia Giuffre’s untimely death has been a shock, especially for those still seeking justice for Jeffrey Epstein’s victims. Giuffre, a key figure in exposing Epstein’s depraved network and its ties to powerful figures like Prince Andrew, was reportedly struck by a bus in Australia. She then apparently ...1 day ago - Bernard’s Dawn Chorus & Pick ‘n’ Mix for Monday, April 28

An official briefing to the Health Minister warns “demand for acute services has outstripped hospital capacity”. Photo: Lynn Grieveson / The KākāThe key long stories short in Aotearoa’s political economy around housing, climate and poverty on Monday, April 28 are: There’s a nationwide shortage of 500 hospital beds and 200,000 ...The KakaBy Bernard Hickey1 day ago

An official briefing to the Health Minister warns “demand for acute services has outstripped hospital capacity”. Photo: Lynn Grieveson / The KākāThe key long stories short in Aotearoa’s political economy around housing, climate and poverty on Monday, April 28 are: There’s a nationwide shortage of 500 hospital beds and 200,000 ...The KakaBy Bernard Hickey1 day ago - Deep sea mining is the new front in Pacific competition

We should have been thinking about the seabed, not so much the cables. When a Chinese research vessel was spotted near Australia’s southern coast in late March, opposition leader Peter Dutton warned the ship was ...The StrategistBy Cynthia Mehboob1 day ago

We should have been thinking about the seabed, not so much the cables. When a Chinese research vessel was spotted near Australia’s southern coast in late March, opposition leader Peter Dutton warned the ship was ...The StrategistBy Cynthia Mehboob1 day ago - Gordon Campbell On A Neglected, Enduring Aspect Of The Francis Era

Now that the formalities of saying goodbye to Pope Francis are over, the process of selecting his successor can begin in earnest. Framing the choice in terms of “liberal v conservative” is somewhat misleading, given that all members of the College of Cardinals uphold the core Catholic doctrines – which ...WerewolfBy ScoopEditor1 day ago

Now that the formalities of saying goodbye to Pope Francis are over, the process of selecting his successor can begin in earnest. Framing the choice in terms of “liberal v conservative” is somewhat misleading, given that all members of the College of Cardinals uphold the core Catholic doctrines – which ...WerewolfBy ScoopEditor1 day ago - 2025 SkS Weekly Climate Change & Global Warming News Roundup #17

A listing of 30 news and opinion articles we found interesting and shared on social media during the past week: Sun, April 20, 2025 thru Sat, April 26, 2025. This week's roundup is again published by category and sorted by number of articles included in each. The formatting is a ...2 days ago

A listing of 30 news and opinion articles we found interesting and shared on social media during the past week: Sun, April 20, 2025 thru Sat, April 26, 2025. This week's roundup is again published by category and sorted by number of articles included in each. The formatting is a ...2 days ago - Governments Are Letting Big Tech Trash Our Planet

Let’s rip the shiny plastic wrapping off a festering truth: planned obsolescence is a deliberate scam, and governments worldwide, including New Zealand’s, are complicit in letting tech giants churn out disposable junk. From flimsy smartphones that croak after two years to laptops with glued-in batteries, the tech industry’s business model ...2 days ago

Let’s rip the shiny plastic wrapping off a festering truth: planned obsolescence is a deliberate scam, and governments worldwide, including New Zealand’s, are complicit in letting tech giants churn out disposable junk. From flimsy smartphones that croak after two years to laptops with glued-in batteries, the tech industry’s business model ...2 days ago - In Loving Memory Of Kyle Whorrall

When I first saw press photos of Mr Whorrall, an America PhD entomology student & researcher who had been living out a dream to finish out his studies in Auckland, my first impression, besides sadness, was how gentle he appeared.Press released the middle photo from Mr Whorrall’s Facebook pageBy all ...Mountain TuiBy Mountain Tūī2 days ago

When I first saw press photos of Mr Whorrall, an America PhD entomology student & researcher who had been living out a dream to finish out his studies in Auckland, my first impression, besides sadness, was how gentle he appeared.Press released the middle photo from Mr Whorrall’s Facebook pageBy all ...Mountain TuiBy Mountain Tūī2 days ago - National’s Betrayal of Renters and First-Time Buyers

It's definitely not a renters market in New Zealand, as reported by 1 News last night. In fact the housing crisis has metastasised into a full-blown catastrophe in 2025, and the National Party Government’s policies are pouring petrol on the flames. Renters are being crushed under skyrocketing costs, first-time buyers ...2 days ago

It's definitely not a renters market in New Zealand, as reported by 1 News last night. In fact the housing crisis has metastasised into a full-blown catastrophe in 2025, and the National Party Government’s policies are pouring petrol on the flames. Renters are being crushed under skyrocketing costs, first-time buyers ...2 days ago - Would I Lie to You?

Would I lie to you? (oh yeah)Would I lie to you honey? (oh, no, no no)Now would I say something that wasn't true?I'm asking you sugar, would I lie to you?Writer(s): David Allan Stewart, Annie Lennox.Opinions issue forth from car radios or the daily news…They demand a bluer National, with ...Nick’s KōreroBy Nick Rockel2 days ago

Would I lie to you? (oh yeah)Would I lie to you honey? (oh, no, no no)Now would I say something that wasn't true?I'm asking you sugar, would I lie to you?Writer(s): David Allan Stewart, Annie Lennox.Opinions issue forth from car radios or the daily news…They demand a bluer National, with ...Nick’s KōreroBy Nick Rockel2 days ago - Fact brief – Do the 31,000 signatures of the OISM Petition Project invalidate the scientific c...

Skeptical Science is partnering with Gigafact to produce fact briefs — bite-sized fact checks of trending claims. You can submit claims you think need checking via the tipline. Do the 31,000 signatures of the OISM Petition Project invalidate the scientific consensus on climate change? Climatologists made up only 0.1% of signatories ...3 days ago

Skeptical Science is partnering with Gigafact to produce fact briefs — bite-sized fact checks of trending claims. You can submit claims you think need checking via the tipline. Do the 31,000 signatures of the OISM Petition Project invalidate the scientific consensus on climate change? Climatologists made up only 0.1% of signatories ...3 days ago - A culture of cruelty.

In the 1980s and early 1990s when I wrote about Argentine and South American authoritarianism, I borrowed the phrase “cultura del miedo” (culture of fear) from Juan Corradi, Guillermo O’Donnell, Norberto Lechner and others to characterise the social anomaly that exists in a country ruled by a state terror regime ...KiwipoliticoBy Pablo3 days ago

In the 1980s and early 1990s when I wrote about Argentine and South American authoritarianism, I borrowed the phrase “cultura del miedo” (culture of fear) from Juan Corradi, Guillermo O’Donnell, Norberto Lechner and others to characterise the social anomaly that exists in a country ruled by a state terror regime ...KiwipoliticoBy Pablo3 days ago - Northern Australia: fortress, gateway and resource powerhouse

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Raelene Lockhorst3 days ago

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Raelene Lockhorst3 days ago - Bernard’s Saturday Soliloquy for the week to April 26

Chris Bishop has unveiled plans for new roads in Tauranga, Auckland and Northland that will cost up to a combined $10 billion. Photo: Lynn GrievesonLong stories short from Aotearoa political economy around housing, poverty and climate in the week to Saturday, April 26:Chris Bishop ploughed ahead this week with spending ...The KakaBy Bernard Hickey3 days ago

Chris Bishop has unveiled plans for new roads in Tauranga, Auckland and Northland that will cost up to a combined $10 billion. Photo: Lynn GrievesonLong stories short from Aotearoa political economy around housing, poverty and climate in the week to Saturday, April 26:Chris Bishop ploughed ahead this week with spending ...The KakaBy Bernard Hickey3 days ago - Debt Is A Form Of Government Control

Unless you've been living under a rock, you would have noticed that New Zealand’s government, under the guise of economic stewardship, is tightening the screws on its citizens, and using debt as a tool of control. This isn’t just a conspiracy theory whispered in pub corners...it’s backed by hard data ...3 days ago

Unless you've been living under a rock, you would have noticed that New Zealand’s government, under the guise of economic stewardship, is tightening the screws on its citizens, and using debt as a tool of control. This isn’t just a conspiracy theory whispered in pub corners...it’s backed by hard data ...3 days ago - The 2025 Budget in a World of Trade Warfare

The budget runup is far from easy.Budget 2025 day is Thursday 22 May. About a month earlier in a normal year, the macroeconomic forecasts would be completed (the fiscal ones would still be tidying up) and the main policy decisions would have been made (but there would still be a ...PunditBy Brian Easton4 days ago

The budget runup is far from easy.Budget 2025 day is Thursday 22 May. About a month earlier in a normal year, the macroeconomic forecasts would be completed (the fiscal ones would still be tidying up) and the main policy decisions would have been made (but there would still be a ...PunditBy Brian Easton4 days ago - EGU2025 – Presentation about our translation activities

As mentioned in the recently published prolog to EGU2025 article, I submitted an abstract to talk about some of our translation activities and the challenges we have been facing with those. This blog post is a "companion article" to that presentation in session EOS4.3 Geoethics and Global Anthropogenic Change: Geoscience for Policy, ...4 days ago

As mentioned in the recently published prolog to EGU2025 article, I submitted an abstract to talk about some of our translation activities and the challenges we have been facing with those. This blog post is a "companion article" to that presentation in session EOS4.3 Geoethics and Global Anthropogenic Change: Geoscience for Policy, ...4 days ago - The drums of war revisited

On 25 April 2021, I published an internal all-staff Anzac Day message. I did so as the Secretary of the Department of Home Affairs, which is responsible for Australia’s civil defence, and its resilience in ...The StrategistBy Michael Pezzullo4 days ago

On 25 April 2021, I published an internal all-staff Anzac Day message. I did so as the Secretary of the Department of Home Affairs, which is responsible for Australia’s civil defence, and its resilience in ...The StrategistBy Michael Pezzullo4 days ago - Cameron Slater’s New Website: Same Old Defamation

You’ve likely noticed that the disgraced blogger of Whale Oil Beef Hooked infamy, Cameron Slater, is still slithering around the internet, peddling his bile on a shiny new blogsite calling itself The Good Oil. If you thought bankruptcy, defamation rulings, and a near-fatal health scare would teach this idiot a ...4 days ago

You’ve likely noticed that the disgraced blogger of Whale Oil Beef Hooked infamy, Cameron Slater, is still slithering around the internet, peddling his bile on a shiny new blogsite calling itself The Good Oil. If you thought bankruptcy, defamation rulings, and a near-fatal health scare would teach this idiot a ...4 days ago - David Seymour’s Atlas Network Receiving Unwanted Attention

The Atlas Network, a sprawling web of libertarian think tanks funded by fossil fuel barons and corporate elites, has sunk its claws into New Zealand’s political landscape. At the forefront of this insidious influence is David Seymour, the ACT Party leader, whose ties to Atlas run deep.With the National Party’s ...4 days ago

The Atlas Network, a sprawling web of libertarian think tanks funded by fossil fuel barons and corporate elites, has sunk its claws into New Zealand’s political landscape. At the forefront of this insidious influence is David Seymour, the ACT Party leader, whose ties to Atlas run deep.With the National Party’s ...4 days ago - Nicola Willis To Blame For Family Boost Debacle

Nicola Willis, National’s supposed Finance Minister, has delivered another policy failure with the Family Boost scheme, a childcare rebate that was big on promises but has been very small on delivery. Only 56,000 families have signed up, a far cry from the 130,000 Willis personally championed in National’s campaign. This ...4 days ago

Nicola Willis, National’s supposed Finance Minister, has delivered another policy failure with the Family Boost scheme, a childcare rebate that was big on promises but has been very small on delivery. Only 56,000 families have signed up, a far cry from the 130,000 Willis personally championed in National’s campaign. This ...4 days ago - Editors’ pick: ‘On the value of military service’

This article was first published on 7 February 2025. In January, I crossed the milestone of 24 years of service in two militaries—the British and Australian armies. It is fair to say that I am ...The StrategistBy Tom McDermott4 days ago

This article was first published on 7 February 2025. In January, I crossed the milestone of 24 years of service in two militaries—the British and Australian armies. It is fair to say that I am ...The StrategistBy Tom McDermott4 days ago - Rest easy, my friend.

He shall grow not old, as we that are left grow old.Age shall not weary him, nor the years condemn.At the going down of the sun and in the morningI will remember him.My mate Keith died yesterday, peacefully in the early hours. My dear friend in Rotorua, whom I’ve been ...Nick’s KōreroBy Nick Rockel4 days ago

He shall grow not old, as we that are left grow old.Age shall not weary him, nor the years condemn.At the going down of the sun and in the morningI will remember him.My mate Keith died yesterday, peacefully in the early hours. My dear friend in Rotorua, whom I’ve been ...Nick’s KōreroBy Nick Rockel4 days ago - The Hoon around the week to April 25

The podcast above of the weekly ‘Hoon’ webinar for paying subscribers on Thursday night features co-hosts & talking about the week’s news with regular and special guests, including: on news New Zealand abstained from a vote on a global shipping levy on climate emissions and downgraded the importance ...The KakaBy Bernard Hickey4 days ago

The podcast above of the weekly ‘Hoon’ webinar for paying subscribers on Thursday night features co-hosts & talking about the week’s news with regular and special guests, including: on news New Zealand abstained from a vote on a global shipping levy on climate emissions and downgraded the importance ...The KakaBy Bernard Hickey4 days ago - The Men Commenting on Lorde

Hi,In case you missed it, New Zealand icon Lorde has a new single out. It’s called “What Was That”, and has a very low key music video that was filmed around her impromptu performance in New York’s Washington Square Park. When police shut down the initial popup, one of my ...David FarrierBy David Farrier4 days ago

Hi,In case you missed it, New Zealand icon Lorde has a new single out. It’s called “What Was That”, and has a very low key music video that was filmed around her impromptu performance in New York’s Washington Square Park. When police shut down the initial popup, one of my ...David FarrierBy David Farrier4 days ago - Skeptical Science New Research for Week #17 2025

Open access notables Internal variability effect doped by climate change drove the 2023 marine heat extreme in the North Atlantic, Guinaldo et al., Communications Earth & Environment The year 2023 shattered numerous heat records both globally and regionally. We here focus on the drivers of the unprecedented warm sea surface temperature (SST) anomalies which started in ...5 days ago

Open access notables Internal variability effect doped by climate change drove the 2023 marine heat extreme in the North Atlantic, Guinaldo et al., Communications Earth & Environment The year 2023 shattered numerous heat records both globally and regionally. We here focus on the drivers of the unprecedented warm sea surface temperature (SST) anomalies which started in ...5 days ago - Military denial: the basis of deterrence, and of response if deterrence fails

A strategy of denial is now the cornerstone concept for Australia’s National Defence Strategy. The term’s use as an overarching guide to defence policy, however, has led to some confusion on what it actually means ...The StrategistBy Iain MacGillivray5 days ago

A strategy of denial is now the cornerstone concept for Australia’s National Defence Strategy. The term’s use as an overarching guide to defence policy, however, has led to some confusion on what it actually means ...The StrategistBy Iain MacGillivray5 days ago - Fiscal failure

The IMF’s twice-yearly World Economic Outlook and Fiscal Monitor publications have come out in the last couple of days. If there is gloom in the GDP numbers (eg this chart for the advanced countries, and we don’t score a lot better on the comparable one for the 2019 to ...Croaking CassandraBy Michael Reddell5 days ago

The IMF’s twice-yearly World Economic Outlook and Fiscal Monitor publications have come out in the last couple of days. If there is gloom in the GDP numbers (eg this chart for the advanced countries, and we don’t score a lot better on the comparable one for the 2019 to ...Croaking CassandraBy Michael Reddell5 days ago - Climate Change: Fucking the ETS again

For a while, it looked like the government had unfucked the ETS, at least insofar as unit settings were concerned. They had to be forced into it by a court case, but at least it got done, and when National came to power, it learned the lesson (and then fucked ...No Right TurnBy Idiot/Savant5 days ago

For a while, it looked like the government had unfucked the ETS, at least insofar as unit settings were concerned. They had to be forced into it by a court case, but at least it got done, and when National came to power, it learned the lesson (and then fucked ...No Right TurnBy Idiot/Savant5 days ago - What’s secret? When is it secret? Well, that’s complicated

The argument over US officials’ misuse of secure but non-governmental messaging platform Signal falls into two camps. Either it is a gross error that undermines national security, or it is a bit of a blunder ...The StrategistBy Kyle McCurdy5 days ago

The argument over US officials’ misuse of secure but non-governmental messaging platform Signal falls into two camps. Either it is a gross error that undermines national security, or it is a bit of a blunder ...The StrategistBy Kyle McCurdy5 days ago - Today’s Headlines: David Seymour’s ECE Risks & Coalition Government Lies

Cost of living ~1/3 of Kiwis needed help with food as cost of living pressures continue to increase - turning to friends, family, food banks or Work and Income in the past year, to find food. 40% of Kiwis also said they felt schemes offered little or no benefit, according ...Mountain TuiBy Mountain Tūī5 days ago

Cost of living ~1/3 of Kiwis needed help with food as cost of living pressures continue to increase - turning to friends, family, food banks or Work and Income in the past year, to find food. 40% of Kiwis also said they felt schemes offered little or no benefit, according ...Mountain TuiBy Mountain Tūī5 days ago - Is The NZ Media Awards Sponsored By a Conspiracy Theorist?

Hi,Perhaps in 2025 it shouldn’t come as a surprise that the CEO and owner of Voyager Internet — the major sponsor of the New Zealand Media Awards — has taken to sharing a variety of Anti-Muslim and anti-Jewish conspiracy theories to his 1.2 million followers.This included sharing a post from ...David FarrierBy David Farrier5 days ago

Hi,Perhaps in 2025 it shouldn’t come as a surprise that the CEO and owner of Voyager Internet — the major sponsor of the New Zealand Media Awards — has taken to sharing a variety of Anti-Muslim and anti-Jewish conspiracy theories to his 1.2 million followers.This included sharing a post from ...David FarrierBy David Farrier5 days ago - Australia-India defence cooperation should be about more than navies

In the sprint to deepen Australia-India defence cooperation, navy links have shot ahead of ties between the two countries’ air forces and armies. That’s largely a good thing: maritime security is at the heart of ...The StrategistBy Kim Heriot-Darragh and Gaurav Saini5 days ago

In the sprint to deepen Australia-India defence cooperation, navy links have shot ahead of ties between the two countries’ air forces and armies. That’s largely a good thing: maritime security is at the heart of ...The StrategistBy Kim Heriot-Darragh and Gaurav Saini5 days ago - When in Rome

'Cause you and me, were meant to be,Walking free, in harmony,One fine day, we'll fly away,Don't you know that Rome wasn't built in a day?Songwriters: Paul David Godfrey / Ross Godfrey / Skye Edwards.I was half expecting to see photos this morning of National Party supporters with wads of cotton ...Nick’s KōreroBy Nick Rockel5 days ago

'Cause you and me, were meant to be,Walking free, in harmony,One fine day, we'll fly away,Don't you know that Rome wasn't built in a day?Songwriters: Paul David Godfrey / Ross Godfrey / Skye Edwards.I was half expecting to see photos this morning of National Party supporters with wads of cotton ...Nick’s KōreroBy Nick Rockel5 days ago - Thursday 24 April

The PSA says a settlement with Health New Zealand over the agency’s proposed restructure of its Data and Digital and Pacific Health teams has saved around 200 roles from being cut. A third of New Zealanders have needed help accessing food in the past year, according to Consumer NZ, and ...NZCTUBy Jack McDonald5 days ago

The PSA says a settlement with Health New Zealand over the agency’s proposed restructure of its Data and Digital and Pacific Health teams has saved around 200 roles from being cut. A third of New Zealanders have needed help accessing food in the past year, according to Consumer NZ, and ...NZCTUBy Jack McDonald5 days ago - John Campbell Investigates Brian Tamaki’s Destiny Church

John Campbell’s Under His Command, a five-part TVNZ+ investigation series starting today, rips the veil off Destiny Church, exposing the rot festering under Brian Tamaki’s self-proclaimed apostolic throne. This isn’t just a church; it’s a fiefdom, built on fear, manipulation, and a trail of scandals that make your stomach churn. ...5 days ago

John Campbell’s Under His Command, a five-part TVNZ+ investigation series starting today, rips the veil off Destiny Church, exposing the rot festering under Brian Tamaki’s self-proclaimed apostolic throne. This isn’t just a church; it’s a fiefdom, built on fear, manipulation, and a trail of scandals that make your stomach churn. ...5 days ago - Decrypting tomorrow’s threats: critical infrastructure needs post-quantum protection today

Some argue we still have time, since quantum computing capable of breaking today’s encryption is a decade or more away. But breakthrough capabilities, especially in domains tied to strategic advantage, rarely follow predictable timelines. Just ...The StrategistBy Jason Van der Schyff5 days ago

Some argue we still have time, since quantum computing capable of breaking today’s encryption is a decade or more away. But breakthrough capabilities, especially in domains tied to strategic advantage, rarely follow predictable timelines. Just ...The StrategistBy Jason Van der Schyff5 days ago - Inside my quest for a climate-friendly bank

This is a re-post from Yale Climate Connections by Pearl Marvell (Photo credit: Pearl Marvell. Image credit: Samantha Harrington. Dollar bill vector image: by pch.vector on Freepik) Igrew up knowing that when you had extra money, you put it under a bed, stashed it in a book or a clock, or, ...5 days ago

This is a re-post from Yale Climate Connections by Pearl Marvell (Photo credit: Pearl Marvell. Image credit: Samantha Harrington. Dollar bill vector image: by pch.vector on Freepik) Igrew up knowing that when you had extra money, you put it under a bed, stashed it in a book or a clock, or, ...5 days ago - Winston Peters Has Lost The Plot

The political petrified piece of wood, Winston Peters, who refuses to retire gracefully, has had an eventful couple of weeks peddling transphobia, pushing bigoted policies, undertaking his unrelenting war on wokeness and slinging vile accusations like calling Green co-leader Chlöe Swarbrick a “groomer”.At 80, the hypocritical NZ First leader’s latest ...5 days ago

The political petrified piece of wood, Winston Peters, who refuses to retire gracefully, has had an eventful couple of weeks peddling transphobia, pushing bigoted policies, undertaking his unrelenting war on wokeness and slinging vile accusations like calling Green co-leader Chlöe Swarbrick a “groomer”.At 80, the hypocritical NZ First leader’s latest ...5 days ago - The one who left

It's raining in Cockermouth and we're following our host up the stairs. We’re telling her it’s a lovely building and she’s explaining that it used to be a pub and a nightclub and a backpackers, but no more.There were floods in 2009 and 2015 along the main street, huge floods, ...More Than A FeildingBy David Slack5 days ago

It's raining in Cockermouth and we're following our host up the stairs. We’re telling her it’s a lovely building and she’s explaining that it used to be a pub and a nightclub and a backpackers, but no more.There were floods in 2009 and 2015 along the main street, huge floods, ...More Than A FeildingBy David Slack5 days ago - Gordon Campbell On The Trump Upside, And Peters Persecution Of Trans People

A recurring aspect of the Trump tariff coverage is that it normalises – or even sanctifies – a status quo that in many respects has been a disaster for working class families. No doubt, Donald Trump is an uncertainty machine that is tanking the stock market and the growth prospects ...WerewolfBy ScoopEditor5 days ago

A recurring aspect of the Trump tariff coverage is that it normalises – or even sanctifies – a status quo that in many respects has been a disaster for working class families. No doubt, Donald Trump is an uncertainty machine that is tanking the stock market and the growth prospects ...WerewolfBy ScoopEditor5 days ago - Is Mark Mitchell a racist?

The National Party’s Minister of Police, Corrections, and Ethnic Communities (irony alert) has stumbled into yet another racist quagmire, proving that when it comes to bigotry, the right wing’s playbook is as predictable as it is vile. This time, Mitchell’s office reposted an Instagram reel falsely claiming that Te Pāti ...6 days ago

The National Party’s Minister of Police, Corrections, and Ethnic Communities (irony alert) has stumbled into yet another racist quagmire, proving that when it comes to bigotry, the right wing’s playbook is as predictable as it is vile. This time, Mitchell’s office reposted an Instagram reel falsely claiming that Te Pāti ...6 days ago - Australian statecraft must restore the link between deterrence and non-proliferation to survive in t...

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Alex Bristow6 days ago

In the week of Australia’s 3 May election, ASPI will release Agenda for Change 2025: preparedness and resilience in an uncertain world, a report promoting public debate and understanding on issues of strategic importance to ...The StrategistBy Alex Bristow6 days ago - J.K. Rowling – Arsehole of the Week

In a world crying out for empathy, J.K. Rowling has once again proven she’s more interested in stoking division than building bridges. The once-beloved author of Harry Potter has cemented her place as this week’s Arsehole of the Week, a title earned through her relentless, tone-deaf crusade against transgender rights. ...6 days ago

In a world crying out for empathy, J.K. Rowling has once again proven she’s more interested in stoking division than building bridges. The once-beloved author of Harry Potter has cemented her place as this week’s Arsehole of the Week, a title earned through her relentless, tone-deaf crusade against transgender rights. ...6 days ago - The rotten, unaccountable crown

Between 1950 and 1993 the New Zealand government tortured and abused up to 250,000 children in residential care facilities. They then proceeded to cover it up in order to minimise their liability, dragging out cases, slandering their victims and ultimately denying redress. In its final report, the Inquiry into Abuse ...No Right TurnBy Idiot/Savant6 days ago

Between 1950 and 1993 the New Zealand government tortured and abused up to 250,000 children in residential care facilities. They then proceeded to cover it up in order to minimise their liability, dragging out cases, slandering their victims and ultimately denying redress. In its final report, the Inquiry into Abuse ...No Right TurnBy Idiot/Savant6 days ago - To prepare for future threats, treat health security as national security

Health security is often seen as a peripheral security domain, and as a problem that is difficult to address. These perceptions weaken our capacity to respond to borderless threats. With the wind back of Covid-19 ...The StrategistBy Susanne Casey6 days ago

Health security is often seen as a peripheral security domain, and as a problem that is difficult to address. These perceptions weaken our capacity to respond to borderless threats. With the wind back of Covid-19 ...The StrategistBy Susanne Casey6 days ago - What’s on the Label -vs- What’s in the Tin.

Would our political parties pass muster under the Fair Trading Act?WHAT IF OUR POLITICAL PARTIES were subject to the Fair Trading Act? What if they, like the nation’s businesses, were prohibited from misleading their consumers – i.e. the voters – about the nature, characteristics, suitability, or quantity of the products ...6 days ago

Would our political parties pass muster under the Fair Trading Act?WHAT IF OUR POLITICAL PARTIES were subject to the Fair Trading Act? What if they, like the nation’s businesses, were prohibited from misleading their consumers – i.e. the voters – about the nature, characteristics, suitability, or quantity of the products ...6 days ago - Simeon Brown Doesn’t Consider Abortion To Be Healthcare As Services Scaled Back

Rod EmmersonThank you to my subscribers and readers - you make it all possible. Tui.Subscribe nowSix updates today from around the world and locally here in Aoteaora New Zealand -1. RFK Jnr’s Autism CrusadeAmerica plans to create a registry of people with autism in the United States. RFK Jr’s department ...Mountain TuiBy Mountain Tūī6 days ago

Rod EmmersonThank you to my subscribers and readers - you make it all possible. Tui.Subscribe nowSix updates today from around the world and locally here in Aoteaora New Zealand -1. RFK Jnr’s Autism CrusadeAmerica plans to create a registry of people with autism in the United States. RFK Jr’s department ...Mountain TuiBy Mountain Tūī6 days ago - Another Munich crisis? Understanding the limits of policymaking by analogy

We see it often enough. A democracy deals with an authoritarian state, and those who oppose concessions cite the lesson of Munich 1938: make none to dictators; take a firm stand. And so we hear ...The StrategistBy Linus Cohen and Chris Taylor6 days ago

We see it often enough. A democracy deals with an authoritarian state, and those who oppose concessions cite the lesson of Munich 1938: make none to dictators; take a firm stand. And so we hear ...The StrategistBy Linus Cohen and Chris Taylor6 days ago - Wednesday 23 April

370 perioperative nurses working at Auckland City Hospital, Starship Hospital and Greenlane Clinical Centre will strike for two hours on 1 May – the same day senior doctors are striking. This is part of nationwide events to mark May Day on 1 May, including rallies outside public hospitals, organised by ...NZCTUBy Jack McDonald6 days ago

370 perioperative nurses working at Auckland City Hospital, Starship Hospital and Greenlane Clinical Centre will strike for two hours on 1 May – the same day senior doctors are striking. This is part of nationwide events to mark May Day on 1 May, including rallies outside public hospitals, organised by ...NZCTUBy Jack McDonald6 days ago - Auckland character rules stop building on 20,000 sections

Character protections for Auckland’s villas have stymied past development. Now moves afoot to strip character protection from a bunch of inner-city villas. Photo: Lynn Grieveson / The KākāLong stories shortest from our political economy on Wednesday, April 23:Special Character Areas designed to protect villas are stopping 20,000 sites near Auckland’s ...The KakaBy Bernard Hickey6 days ago

Character protections for Auckland’s villas have stymied past development. Now moves afoot to strip character protection from a bunch of inner-city villas. Photo: Lynn Grieveson / The KākāLong stories shortest from our political economy on Wednesday, April 23:Special Character Areas designed to protect villas are stopping 20,000 sites near Auckland’s ...The KakaBy Bernard Hickey6 days ago - AI is changing Indo-Pacific naval operations

Artificial intelligence is poised to significantly transform the Indo-Pacific maritime security landscape. It offers unprecedented situational awareness, decision-making speed and operational flexibility. But without clear rules, shared norms and mechanisms for risk reduction, AI could ...The StrategistBy Jihoon Yu6 days ago

Artificial intelligence is poised to significantly transform the Indo-Pacific maritime security landscape. It offers unprecedented situational awareness, decision-making speed and operational flexibility. But without clear rules, shared norms and mechanisms for risk reduction, AI could ...The StrategistBy Jihoon Yu6 days ago - What is a Man?

For what is a man, what has he got?If not himself, then he has naughtTo say the things he truly feelsAnd not the words of one who kneelsThe record showsI took the blowsAnd did it my wayLyrics: Paul Anka.Morena folks, before we discuss Winston’s latest salvo in NZ First’s War ...Nick’s KōreroBy Nick Rockel6 days ago

For what is a man, what has he got?If not himself, then he has naughtTo say the things he truly feelsAnd not the words of one who kneelsThe record showsI took the blowsAnd did it my wayLyrics: Paul Anka.Morena folks, before we discuss Winston’s latest salvo in NZ First’s War ...Nick’s KōreroBy Nick Rockel6 days ago - Britain recasts AUKUS for a new era

Britain once risked a reputation as the weak link in the trilateral AUKUS partnership. But now the appointment of an empowered senior official to drive the project forward and a new burst of British parliamentary ...The StrategistBy Sophia Gaston7 days ago

Britain once risked a reputation as the weak link in the trilateral AUKUS partnership. But now the appointment of an empowered senior official to drive the project forward and a new burst of British parliamentary ...The StrategistBy Sophia Gaston7 days ago - Australia’s basic-metals problem: old plants and subsidised Chinese competition

Australia’s ability to produce basic metals, including copper, lead, zinc, nickel and construction steel, is in jeopardy, with ageing plants struggling against Chinese competition. The multinational commodities company Trafigura has put its Australian operations under ...The StrategistBy David Uren7 days ago

Australia’s ability to produce basic metals, including copper, lead, zinc, nickel and construction steel, is in jeopardy, with ageing plants struggling against Chinese competition. The multinational commodities company Trafigura has put its Australian operations under ...The StrategistBy David Uren7 days ago - Rob Campbell – Public Private Partnerships: What a Good Idea! OR ‘There will be no free...

There have been recent PPP debacles, both in New Zealand (think Transmission Gully) and globally, with numerous examples across both Australia and Britain of failed projects and extensive litigation by government agencies seeking redress for the failures.Rob Campbell is one of New Zealand’s sharpest critics of PPPs noting that; "There ...7 days ago

There have been recent PPP debacles, both in New Zealand (think Transmission Gully) and globally, with numerous examples across both Australia and Britain of failed projects and extensive litigation by government agencies seeking redress for the failures.Rob Campbell is one of New Zealand’s sharpest critics of PPPs noting that; "There ...7 days ago - RB spending: the Board and the Minister

On Twitter on Saturday I indicated that there had been a mistake in my post from last Thursday in which I attempted to step through the Reserve Bank Funding Agreement issues. Making mistakes (there are two) is annoying and I don’t fully understand how I did it (probably too much ...Croaking CassandraBy Michael Reddell7 days ago

On Twitter on Saturday I indicated that there had been a mistake in my post from last Thursday in which I attempted to step through the Reserve Bank Funding Agreement issues. Making mistakes (there are two) is annoying and I don’t fully understand how I did it (probably too much ...Croaking CassandraBy Michael Reddell7 days ago - Indonesia needs to rethink its approach to military drones

Indonesia’s armed forces still have a lot of work to do in making proper use of drones. Two major challenges are pilot training and achieving interoperability between the services. Another is overcoming a predilection for ...The StrategistBy Sandy Juda Pratama, Curie Maharani and Gautama Adi Kusuma7 days ago

Indonesia’s armed forces still have a lot of work to do in making proper use of drones. Two major challenges are pilot training and achieving interoperability between the services. Another is overcoming a predilection for ...The StrategistBy Sandy Juda Pratama, Curie Maharani and Gautama Adi Kusuma7 days ago - Help Stop the Gaza Genocide Through Activism

As a living breathing human being, you’ve likely seen the heart-wrenching images from Gaza...homes reduced to rubble, children burnt to cinders, families displaced, and a death toll that’s beyond comprehension. What is going on in Gaza is most definitely a genocide, the suffering is real, and it’s easy to feel ...7 days ago

As a living breathing human being, you’ve likely seen the heart-wrenching images from Gaza...homes reduced to rubble, children burnt to cinders, families displaced, and a death toll that’s beyond comprehension. What is going on in Gaza is most definitely a genocide, the suffering is real, and it’s easy to feel ...7 days ago - Willis ignores new Global Financial & Trade Crisis

Donald Trump, who has called the Chair of the Federal Reserve “a major loser”. Photo: Getty ImagesLong stories shortest from our political economy on Tuesday, April 22:US markets slump after Donald Trump threatens the Fed’s independence. China warns its trading partners not to side with the US. Trump says some ...The KakaBy Bernard Hickey1 week ago

Donald Trump, who has called the Chair of the Federal Reserve “a major loser”. Photo: Getty ImagesLong stories shortest from our political economy on Tuesday, April 22:US markets slump after Donald Trump threatens the Fed’s independence. China warns its trading partners not to side with the US. Trump says some ...The KakaBy Bernard Hickey1 week ago - One of the Good Ones

Nick’s KōreroBy Nick Rockel1 week ago

Related Posts

- Ban on engineered stone essential to protect workers

The Green Party has renewed its call for the Government to ban the use, supply, and manufacture of engineered stone products, as the CTU launches a petition for the implementation of a full ban. ...24 hours ago

The Green Party has renewed its call for the Government to ban the use, supply, and manufacture of engineered stone products, as the CTU launches a petition for the implementation of a full ban. ...24 hours ago - Release: Anzac Day a time to recommit to veterans

4 days ago

- Education Should be Led by Experts-Not Economists

Te Pāti Māori are appalled by Cabinet's decision to agree to 15 recommendations to the Early Childhood Education (ECE) sector following the regulatory review by the Ministry of Regulation. We emphasise the need to prioritise tamariki Māori in Early Childhood Education, conducted by education experts- not economists. “Our mokopuna deserve ...5 days ago

Te Pāti Māori are appalled by Cabinet's decision to agree to 15 recommendations to the Early Childhood Education (ECE) sector following the regulatory review by the Ministry of Regulation. We emphasise the need to prioritise tamariki Māori in Early Childhood Education, conducted by education experts- not economists. “Our mokopuna deserve ...5 days ago - Release: Govt’s flagship cost of living policy a failure

After promising $250 a fortnight to many families, the Government has been forced to admit just a couple hundred families are receiving it. ...5 days ago

After promising $250 a fortnight to many families, the Government has been forced to admit just a couple hundred families are receiving it. ...5 days ago - Release: Transparency needed on changes to early childhood education

The Government is putting children at risk in early childhood education (ECE) by proposing to loosen the requirement for qualified teachers. ...5 days ago

The Government is putting children at risk in early childhood education (ECE) by proposing to loosen the requirement for qualified teachers. ...5 days ago - Release: Govt funding needed to combat invasive seaweed

The Government must support Northland hapū who have resorted to rakes and buckets to try to control a devastating invasive seaweed that threatens the local economy and environment. ...7 days ago

The Government must support Northland hapū who have resorted to rakes and buckets to try to control a devastating invasive seaweed that threatens the local economy and environment. ...7 days ago - New Zealand First Introduces Bill Defining ‘Woman’ and ‘Man’ in Law

New Zealand First has today introduced a Member’s Bill that would ensure the biological definition of a woman and man are defined in law. “This is not about being anti-anyone or anti-anything. This is about ensuring we as a country focus on the facts of biology and protect the ...7 days ago

New Zealand First has today introduced a Member’s Bill that would ensure the biological definition of a woman and man are defined in law. “This is not about being anti-anyone or anti-anything. This is about ensuring we as a country focus on the facts of biology and protect the ...7 days ago - Release: Labour marks the passing of Pope Francis

1 week ago

- Release: Boot camps blog post fails to provide clarity

After stonewalling requests for information on boot camps, the Government has now offered up a blog post right before Easter weekend rather than provide clarity on the pilot. ...2 weeks ago

After stonewalling requests for information on boot camps, the Government has now offered up a blog post right before Easter weekend rather than provide clarity on the pilot. ...2 weeks ago - Release: Inflation rises and families feel the squeeze

2 weeks ago

- Release: Govt doesn’t know how to fund new hospitals

The Government’s health infrastructure plan is big on promises but coy on where the money is coming from. ...2 weeks ago

The Government’s health infrastructure plan is big on promises but coy on where the money is coming from. ...2 weeks ago - Release: $10 million for only 215 students in charter schools

David Seymour is pouring $10 million into charter schools that only have 215 students enrolled. ...2 weeks ago

David Seymour is pouring $10 million into charter schools that only have 215 students enrolled. ...2 weeks ago - Release: Food prices further stretching the family budget

Families already stretched by rising costs will struggle with the news food prices are going up again. ...2 weeks ago

Families already stretched by rising costs will struggle with the news food prices are going up again. ...2 weeks ago - Release: Mental health staff and patients at risk without plan

More people could be harmed if Minister for Mental Health Matt Doocey does not guarantee to protect patients and workers as the Police withdraw from supporting mental health call outs. ...2 weeks ago

More people could be harmed if Minister for Mental Health Matt Doocey does not guarantee to protect patients and workers as the Police withdraw from supporting mental health call outs. ...2 weeks ago - Release: Driver licensing proposal doesn’t put safety first

The Government’s proposal to change driver licensing rules is a mixed bag of sensible and careless. ...2 weeks ago

The Government’s proposal to change driver licensing rules is a mixed bag of sensible and careless. ...2 weeks ago - Release: Students struggling as Govt sits on hands

The Government is continuing to sit on its hands as students struggle to pay rent due to delays with StudyLink. ...3 weeks ago

The Government is continuing to sit on its hands as students struggle to pay rent due to delays with StudyLink. ...3 weeks ago - Release: More must be done to stop children going hungry

More children are going hungry and statistics showing children in material hardship continue to get worse. ...3 weeks ago

More children are going hungry and statistics showing children in material hardship continue to get worse. ...3 weeks ago - Greens continue to call for Pacific Visa Waiver

The Green Party recognises the extension of visa allowances for our Pacific whānau as a step in the right direction but continues to call for a Pacific Visa Waiver. ...3 weeks ago

The Green Party recognises the extension of visa allowances for our Pacific whānau as a step in the right direction but continues to call for a Pacific Visa Waiver. ...3 weeks ago - More children going hungry under Coalition govt

The Government yesterday released its annual child poverty statistics, and by its own admission, more tamariki across Aotearoa are now living in material hardship. ...3 weeks ago

The Government yesterday released its annual child poverty statistics, and by its own admission, more tamariki across Aotearoa are now living in material hardship. ...3 weeks ago - Release: Longer wait for treatment under National

New Zealanders have waited longer to get an appointment with a specialist and to get elective surgery under the National Government. ...3 weeks ago

New Zealanders have waited longer to get an appointment with a specialist and to get elective surgery under the National Government. ...3 weeks ago - Ka mate te Pire- Ka ora te mana o Te Tiriti o Waitangi me te iwi Māori

Today, Te Pāti Māori join the motu in celebration as the Treaty Principles Bill is voted down at its second reading. “From the beginning, this Bill was never welcome in this House,” said Te Pāti Māori Co-Leader, Rawiri Waititi. “Our response to the first reading was one of protest: protesting ...3 weeks ago

Today, Te Pāti Māori join the motu in celebration as the Treaty Principles Bill is voted down at its second reading. “From the beginning, this Bill was never welcome in this House,” said Te Pāti Māori Co-Leader, Rawiri Waititi. “Our response to the first reading was one of protest: protesting ...3 weeks ago - Chris Hipkins speech: Treaty Principles Bill second reading

Normally, when I rise in this House to speak on a bill, I say it's a great privilege to speak on the bill. That is not the case today. ...3 weeks ago

Normally, when I rise in this House to speak on a bill, I say it's a great privilege to speak on the bill. That is not the case today. ...3 weeks ago - Release: End to the Treaty Principles Bill, but challenges remain ahead for Aotearoa

3 weeks ago

- Ka mate te Pire, ka ora Te Tiriti o Waitangi – Treaty Principles Bill dead, Te Tiriti o Waitangi m...

The Green Party is proud to have voted down the Coalition Government’s Treaty Principles Bill, an archaic piece of legislation that sought to attack the nation’s founding agreement. ...3 weeks ago

The Green Party is proud to have voted down the Coalition Government’s Treaty Principles Bill, an archaic piece of legislation that sought to attack the nation’s founding agreement. ...3 weeks ago - Member’s Bill an opportunity for climate action

A Member’s Bill in the name of Green Party MP Julie Anne Genter which aims to stop coal mining, the Crown Minerals (Prohibition of Mining) Amendment Bill, has been pulled from Parliament’s ‘biscuit tin’ today. ...3 weeks ago

A Member’s Bill in the name of Green Party MP Julie Anne Genter which aims to stop coal mining, the Crown Minerals (Prohibition of Mining) Amendment Bill, has been pulled from Parliament’s ‘biscuit tin’ today. ...3 weeks ago - Release: Bill to make trading laws fairer passes first hurdle

Labour MP Kieran McAnulty’s Members Bill to make the law simpler and fairer for businesses operating on Easter, Anzac and Christmas Days has passed its first reading after a conscience vote in Parliament. ...3 weeks ago

Labour MP Kieran McAnulty’s Members Bill to make the law simpler and fairer for businesses operating on Easter, Anzac and Christmas Days has passed its first reading after a conscience vote in Parliament. ...3 weeks ago - Release: Reserve Bank acts while Govt shrugs

Nicola Willis continues to sit on her hands amid a global economic crisis, leaving the Reserve Bank to act for New Zealanders who are worried about their jobs, mortgages, and KiwiSaver. ...3 weeks ago

Nicola Willis continues to sit on her hands amid a global economic crisis, leaving the Reserve Bank to act for New Zealanders who are worried about their jobs, mortgages, and KiwiSaver. ...3 weeks ago - Release: Property Law Amendment Bill pulled from ballot

A Bill to protect first home buyers and others from bad faith property vendors has been drawn from the Member’s Ballot. ...3 weeks ago

A Bill to protect first home buyers and others from bad faith property vendors has been drawn from the Member’s Ballot. ...3 weeks ago - Release: More children at risk of losing family connections

Karen Chhour is proposing to scrap Oranga Tamariki targets which aim to connect more children under state care with family and their culture. ...3 weeks ago

Karen Chhour is proposing to scrap Oranga Tamariki targets which aim to connect more children under state care with family and their culture. ...3 weeks ago

Related Posts

- Arsenic is everywhere – but new detection methods could help save lives

Source: The Conversation (Au and NZ) – By Magdalena Wajrak, Senior Lecturer in Chemistry, Edith Cowan University Arsenic is a nasty poison that once reigned as the ultimate weapon of deception. In the 18th century, it was the poison of choice for those wanting to kill their enemies and spouses, ...Evening ReportBy The Conversation1 hour ago

Source: The Conversation (Au and NZ) – By Magdalena Wajrak, Senior Lecturer in Chemistry, Edith Cowan University Arsenic is a nasty poison that once reigned as the ultimate weapon of deception. In the 18th century, it was the poison of choice for those wanting to kill their enemies and spouses, ...Evening ReportBy The Conversation1 hour ago - Forming new habits can take longer than you think. Here are 8 tips to help you stick with them

Source: The Conversation (Au and NZ) – By Ben Singh, Research Fellow, Allied Health & Human Performance, University of South Australia SarahMcEwan/Shutterstock If you’ve ever tried to build a new habit – whether that’s exercising more, eating healthier, or going to bed earlier – you may have heard the ...Evening ReportBy The Conversation1 hour ago

Source: The Conversation (Au and NZ) – By Ben Singh, Research Fellow, Allied Health & Human Performance, University of South Australia SarahMcEwan/Shutterstock If you’ve ever tried to build a new habit – whether that’s exercising more, eating healthier, or going to bed earlier – you may have heard the ...Evening ReportBy The Conversation1 hour ago - ‘Complaining is career suicide’: the hidden mental health crisis turning our screen industry ups...

Source: The Conversation (Au and NZ) – By Peter Hegedus, Associate Professor, Griffith Film School, Griffith University Shutterstock The Australian screen industry is often associated with fun, creativity and perhaps even glamour. But our new Pressure Point Report reveals a more troubling reality: a pervasive mental health crisis, which ...Evening ReportBy The Conversation1 hour ago

Source: The Conversation (Au and NZ) – By Peter Hegedus, Associate Professor, Griffith Film School, Griffith University Shutterstock The Australian screen industry is often associated with fun, creativity and perhaps even glamour. But our new Pressure Point Report reveals a more troubling reality: a pervasive mental health crisis, which ...Evening ReportBy The Conversation1 hour ago - The cost of being: A ‘reformed spender’ trying to pay off their mortgage ASAP

As part of our series exploring how New Zealanders live and our relationship with money, a contractor explains how she went from living beyond her means in her 20s to being a dedicated saver in her 40s, with the help of finance podcasts and blogs. Want to be part of The ...The SpinoffBy The Cost of Being1 hour ago

As part of our series exploring how New Zealanders live and our relationship with money, a contractor explains how she went from living beyond her means in her 20s to being a dedicated saver in her 40s, with the help of finance podcasts and blogs. Want to be part of The ...The SpinoffBy The Cost of Being1 hour ago - $1b cut to operating allowance coming in Budget, Nicola Willis says

The government will slash its operating allowance from $2.4 billion to $1.3b, Nicola Willis says. ...1 hour ago

The government will slash its operating allowance from $2.4 billion to $1.3b, Nicola Willis says. ...1 hour ago - New survey shows business outlook is weakening and uncertainty rising as the trade war bites

Source: The Conversation (Au and NZ) – By John Simon, Adjunct Fellow in Economics, Macquarie University Vivid Brands/Shutterstock Uncertainty is everywhere these days. There is even uncertainty about the uncertainty. The Reserve Bank of Australia, for example, noted in the minutes from its April 1 meeting: The most ...Evening ReportBy The Conversation2 hours ago

Source: The Conversation (Au and NZ) – By John Simon, Adjunct Fellow in Economics, Macquarie University Vivid Brands/Shutterstock Uncertainty is everywhere these days. There is even uncertainty about the uncertainty. The Reserve Bank of Australia, for example, noted in the minutes from its April 1 meeting: The most ...Evening ReportBy The Conversation2 hours ago - How ICE is becoming a secret police force under the Trump administration

Source: The Conversation (Au and NZ) – By Lee Morgenbesser, Associate Professor, School of Government and International Relations, Griffith University Secret police are a quintessential feature of authoritarian regimes. From Azerbaijan’s State Security Service to Zimbabwe’s Central Intelligence Organisation, these agencies typically target political opponents and dissidents through covert surveillance, ...Evening ReportBy The Conversation2 hours ago

Source: The Conversation (Au and NZ) – By Lee Morgenbesser, Associate Professor, School of Government and International Relations, Griffith University Secret police are a quintessential feature of authoritarian regimes. From Azerbaijan’s State Security Service to Zimbabwe’s Central Intelligence Organisation, these agencies typically target political opponents and dissidents through covert surveillance, ...Evening ReportBy The Conversation2 hours ago - Democracy on display or a public eyesore? The case for cracking down on election corflutes

Source: The Conversation (Au and NZ) – By Andrew Hughes, Lecturer in Marketing, Research School of Management, Australian National University In my time researching political advertising, one common communication method that often generates complaints is the proliferation of campaign corflutes. Politicians love them. Not so, many members of the general ...Evening ReportBy The Conversation2 hours ago

Source: The Conversation (Au and NZ) – By Andrew Hughes, Lecturer in Marketing, Research School of Management, Australian National University In my time researching political advertising, one common communication method that often generates complaints is the proliferation of campaign corflutes. Politicians love them. Not so, many members of the general ...Evening ReportBy The Conversation2 hours ago - Here’s how to make your backyard safer and cooler next summer

Source: The Conversation (Au and NZ) – By Pui Kwan Cheung, Research Fellow in Urban Microclimates, The University of Melbourne Varavin88, Shutterstock Our backyards should be safe and inviting spaces all year round, including during the summer months. But the choices we make about garden design and maintenance, ...Evening ReportBy The Conversation2 hours ago

Source: The Conversation (Au and NZ) – By Pui Kwan Cheung, Research Fellow in Urban Microclimates, The University of Melbourne Varavin88, Shutterstock Our backyards should be safe and inviting spaces all year round, including during the summer months. But the choices we make about garden design and maintenance, ...Evening ReportBy The Conversation2 hours ago - Andrew Little Acknowledges Tory Whanau’s Service To Wellington

“My focus remains on campaigning to win a mandate for change at the local elections in October. As I speak with people across our city, it’s clear that Wellington faces significant challenges that require urgent attention”, Andrew Little says. ...2 hours ago

“My focus remains on campaigning to win a mandate for change at the local elections in October. As I speak with people across our city, it’s clear that Wellington faces significant challenges that require urgent attention”, Andrew Little says. ...2 hours ago - Watch live: $1b cut to operating allowance coming in Budget, Nicola Willis says

The government will slash its operating allowance from $2.4 billion to $1.3b, Nicola Willis says. ...3 hours ago

The government will slash its operating allowance from $2.4 billion to $1.3b, Nicola Willis says. ...3 hours ago - Tory Whanau’s withdrawal upends race for Wellington mayor

The mayor is clearing the path for Andrew Little, saying she doesn’t want a ‘Green vs. Labour narrative to distract from what’s important for our city’, writes Catherine McGregor in today’s extract from The Bulletin. To receive The Bulletin in full each weekday, sign up here. Whanau steps aside for a ...The SpinoffBy Catherine McGregor3 hours ago

The mayor is clearing the path for Andrew Little, saying she doesn’t want a ‘Green vs. Labour narrative to distract from what’s important for our city’, writes Catherine McGregor in today’s extract from The Bulletin. To receive The Bulletin in full each weekday, sign up here. Whanau steps aside for a ...The SpinoffBy Catherine McGregor3 hours ago - Luxon’s War On Nature Opens Gate For More Dairy Conversion

Greenpeace spokesperson Will Appelbe says, "Everyone, no matter where they live, should be able to drink the water from their kitchen tap without getting sick. But this basic right is under threat by an already oversized intensive dairy industry ...3 hours ago

Greenpeace spokesperson Will Appelbe says, "Everyone, no matter where they live, should be able to drink the water from their kitchen tap without getting sick. But this basic right is under threat by an already oversized intensive dairy industry ...3 hours ago - ACT drafts member’s bill to remove banking climate disclosures

4 hours ago

- Healthcare providers funding immunisations out of own pockets, Health NZ admits ‘work to do...

Health NZ admits there is still some work to do, as Māori and Pacific immunisation providers say funding is too low to cover services. ...5 hours ago

Health NZ admits there is still some work to do, as Māori and Pacific immunisation providers say funding is too low to cover services. ...5 hours ago - Auckland iwi boss accuses NZ First, ACT MPs of ‘scaremongering’ with Waitākere Ranges c...

Shane Jones and David Seymour are against a proposal for Te Kawerau ā Maki to be part of a committee overseeing the Waitākere Ranges. ...5 hours ago

Shane Jones and David Seymour are against a proposal for Te Kawerau ā Maki to be part of a committee overseeing the Waitākere Ranges. ...5 hours ago - Five ways to make cities more resilient to climate change

Source: The Conversation (Au and NZ) – By Paul O’Hare, Lecturer in Human Geography and Urban Development, Manchester Metropolitan University John_T/Shutterstock Climate breakdown poses immense threats to global economies, societies and ecosystems. Adapting to these impacts is urgent. But many cities and countries remain chronically unprepared in what the ...Evening ReportBy The Conversation5 hours ago

Source: The Conversation (Au and NZ) – By Paul O’Hare, Lecturer in Human Geography and Urban Development, Manchester Metropolitan University John_T/Shutterstock Climate breakdown poses immense threats to global economies, societies and ecosystems. Adapting to these impacts is urgent. But many cities and countries remain chronically unprepared in what the ...Evening ReportBy The Conversation5 hours ago - Chatham Islands hopes for a more independent future

New Zealand's remotest community relies heavily on public money, but it's not what the community wants for itself. ...5 hours ago

New Zealand's remotest community relies heavily on public money, but it's not what the community wants for itself. ...5 hours ago - Windbag: The rise and fall of character areas

After the high court backed Wellington City Council’s decision to reduce the city’s character areas, Joel MacManus looks back at the five decades that shaped the restrictive housing policy. The motorway came and tore the community in two. A great big gash of concrete. Eight lanes of destruction and separation. ...The SpinoffBy Joel MacManus5 hours ago